Injection Molding in San Antonio: A Comprehensive Guide

Injection molding has revolutionized the manufacturing landscape, particularly in sectors such as electronics and medical supplies. In San Antonio, this technique has found fertile ground, driven by a robust industrial ecosystem and a commitment to quality innovation.

Understanding Injection Molding

At its core, injection molding is a manufacturing process for producing parts by injecting molten material into a mold. This method can be used for a variety of materials, including plastics, metals, and ceramics, but it is most commonly associated with plastic components. The process offers numerous advantages, including:

- High Efficiency: Once the mold is created, injection molding can produce thousands of parts quickly and consistently.

- Complex Geometries: Intricate designs that would be impossible to create with traditional methods can be easily realized.

- Material Versatility: A wide range of materials can be used, allowing businesses to select the most suitable for their needs.

The Role of San Antonio in Injection Molding

San Antonio has emerged as a key player in the injection molding industry due to its strategic location, access to talent, and supportive business environment. The city's diverse economy, which includes significant contributions from the electronics and medical segments, has fostered the growth of manufacturing capabilities.

A Growing Industrial Hub

With a solid infrastructure network and proximity to major markets, San Antonio is ideally situated for companies specializing in injection molding. The local workforce is skilled and experienced, particularly in high-tech industries like electronics and healthcare, where precision and quality are paramount.

The Importance of High-Quality Injection Molding

In industries such as medical technology, the stakes are particularly high. Parts must not only meet stringent regulatory standards but also be reliable and safe. Companies like Nolato lead the way in ensuring quality by employing advanced manufacturing techniques, rigorous quality control, and adherence to international standards.

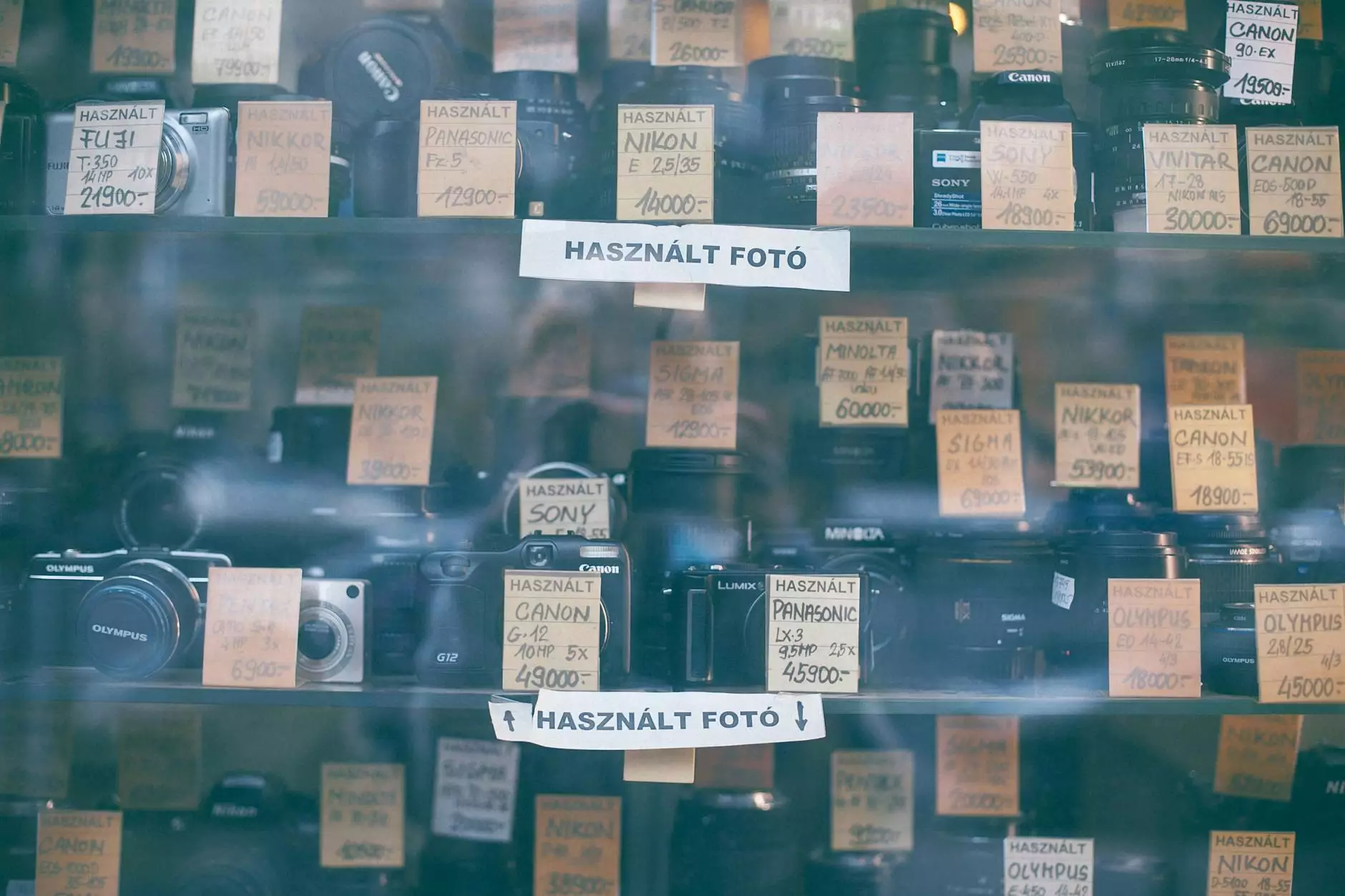

Applications of Injection Molding in Electronics

The electronic components market requires consistent quality and precision, making injection molding an ideal manufacturing technique. Popular applications include:

- Casings and Housings: The exterior shells for devices are often created using injection molding, providing a durable and attractive finish.

- Connectors and Components: Small parts like connectors can be produced with high accuracy, ensuring they function correctly within systems.

- Insulation and Encapsulation: Many electronic components require encapsulation for protection against environmental factors.

Health and Safety in Medical Injection Molding

The medical field demands the highest level of manufacturing excellence. Injection molding is utilized for:

- Medical Devices: Many devices are produced through this method, enabling complex designs that are essential for functionality.

- Single-Use Products: Items such as syringes and surgical tools benefit from high-volume production techniques.

- PPE and Diagnostic Tools: As the world moves towards more preventive healthcare, the demand for personal protective equipment and diagnostic tools is rising.

Advantages of Partnering with Nolato for Injection Molding

Nolato is a leader in the field of injection molding, especially in the challenging sectors of electronics and medical supplies. Here are some reasons to consider partnering with Nolato:

- Expertise: With decades of experience, Nolato brings unparalleled expertise in manufacturing and supplying high-quality components.

- Innovation: The company continuously invests in the latest technology, ensuring that they utilize cutting-edge processes.

- Customization: Nolato understands the unique needs of clients and offers tailored solutions for specific project requirements.

Maintaining Quality Standards

Quality assurance is vital in both electronics and healthcare. Nolato adheres to strict industry standards, including ISO certifications. Their rigorous testing protocols ensure that every part produced meets the highest specifications. This not only minimizes defects but also enhances customer satisfaction and compliance with regulatory requirements.

Continuous Improvement and Sustainability

Nolato is committed to sustainable practices, implementing initiatives to reduce waste and improve energy efficiency throughout the manufacturing process. This focus on sustainability not only benefits the environment but also appeals to a growing number of consumers seeking eco-friendly products.

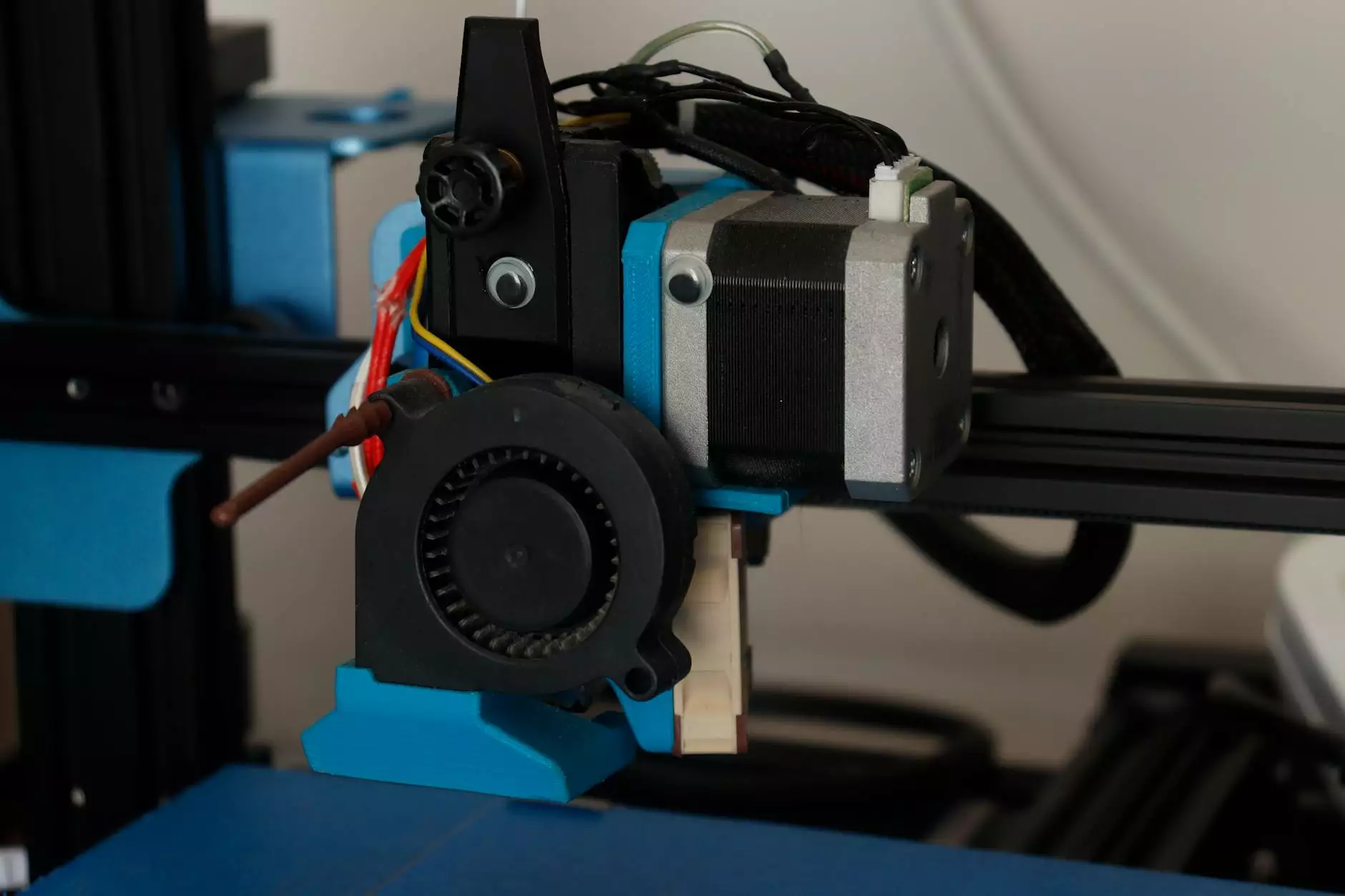

The Future of Injection Molding in San Antonio

As technology evolves, so does the potential for injection molding in San Antonio. The future holds exciting developments, including:

- 3D Printing Integration: The marriage of injection molding and additive manufacturing could lead to even more innovative solutions.

- Smart Manufacturing: IoT and automation technologies are set to enhance production efficiency and data analytics capabilities.

- Increased Focus on Biocompatibility: With growing demands in the medical sector, more research is being conducted into biocompatible materials that can be used in injection molding.

Conclusion

In conclusion, injection molding in San Antonio is a dynamic and growing field that plays an essential role in key industries like electronics and medical supplies. By choosing a certified leader like Nolato, businesses can ensure they are leveraging top-tier manufacturing capabilities, advanced technology, and a commitment to quality that is vital in today’s competitive environment. The continually evolving landscape promises even greater innovations and opportunities for growth, making it an exciting time to engage with this pivotal manufacturing process.