The Power of 3D Printing for Road Cleaning Trucks

Introduction

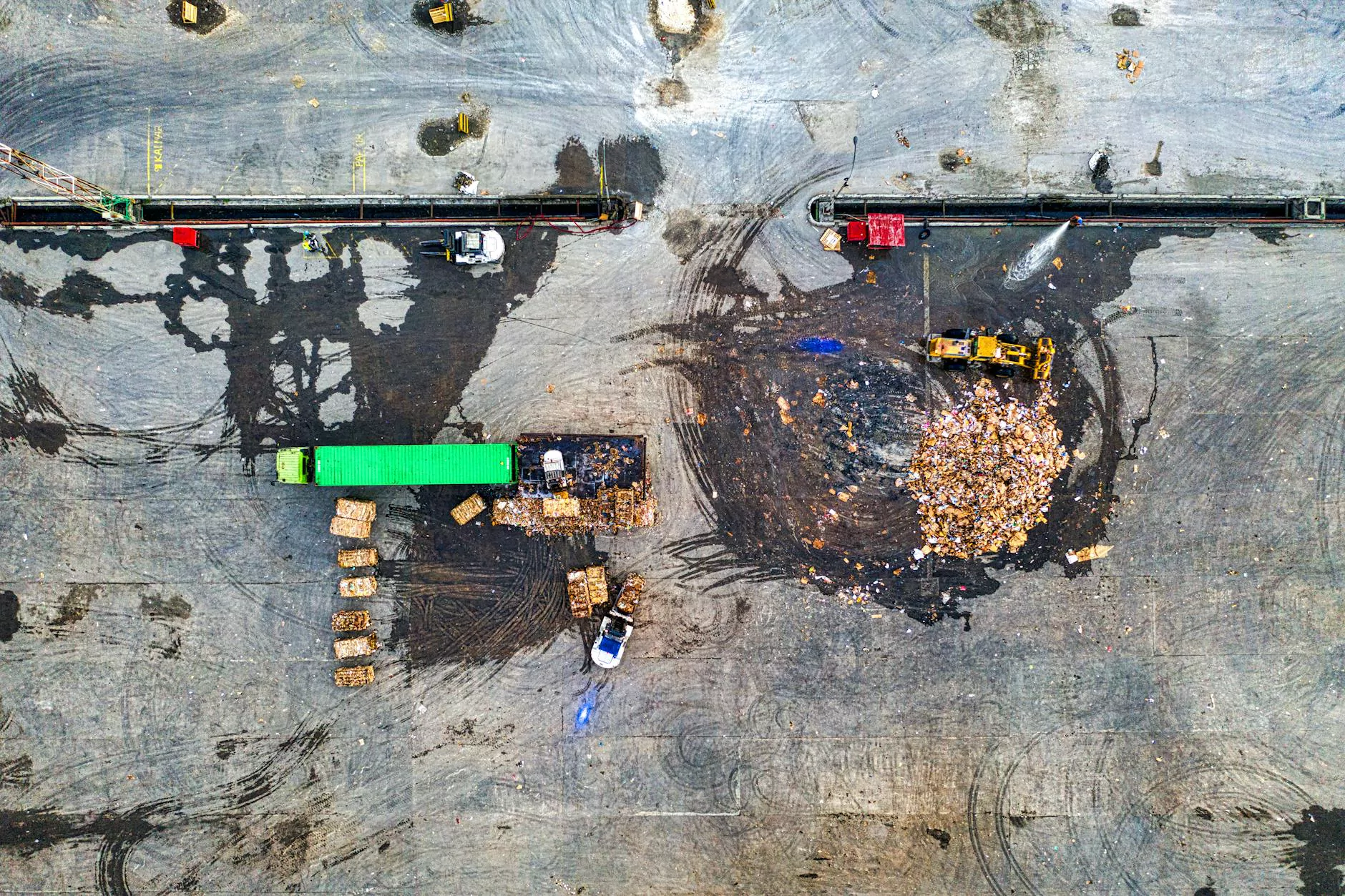

In the world of road cleaning trucks, staying ahead of the competition is crucial to ensure efficient operations and customer satisfaction. One cutting-edge technology that has revolutionized the industry is 3D printing. Ceksan Sweepers, a leading manufacturer in the sector, has successfully incorporated this innovative solution to raise the bar in performance and efficiency.

The Benefits of 3D Printing

3D printing has gained significant traction in various industries over the years, and road cleaning trucks are no exception. Let's explore the incredible benefits it brings to the table:

1. Customization and Flexibility

With 3D printing, Ceksan Sweepers can easily customize various components of their road cleaning trucks according to specific client requirements. This new level of flexibility allows tailoring the equipment to match different environments, road conditions, and cleaning demands. Whether it's the size and shape of brushes or the design of waste containers, the possibilities are endless.

2. Enhanced Performance

By integrating 3D printed parts, Ceksan Sweepers achieves improved performance in their road cleaning trucks. The lightweight nature of 3D printed components reduces the overall vehicle weight, resulting in increased fuel efficiency and reduced emissions. Moreover, the use of advanced materials ensures high durability, extending the lifespan of the equipment and reducing maintenance costs.

3. Rapid Prototyping and Innovation

3D printing enables Ceksan Sweepers to quickly create prototypes of new designs and innovations. This significantly speeds up the development cycle, allowing for faster iterations, testing, and validation. By harnessing this technology, Ceksan Sweepers can stay ahead of market demands, continuously improving their road cleaning trucks and offering state-of-the-art solutions to their customers.

4. Cost Savings

Traditional manufacturing methods often involve high setup costs and time-consuming processes. 3D printing eliminates the need for expensive molds or tooling, resulting in substantial cost savings for Ceksan Sweepers. Additionally, the ability to print on-demand significantly reduces inventory costs and eliminates wastage, as parts can be produced as and when needed.

Implementing 3D Printing at Ceksan Sweepers

Ceksan Sweepers has embraced the potential of 3D printing technology by establishing a dedicated research and development team. This team works tirelessly to identify areas where 3D printing can be applied to their road cleaning trucks, as well as optimize existing designs for improved performance and efficiency.

The key steps involved in implementing 3D printing at Ceksan Sweepers include:

1. Design Optimization

The R&D team conducts in-depth analyses and simulations to identify components that can be optimized using 3D printing. By utilizing computer-aided design (CAD) software, they create intricate and precise models while ensuring they meet the required specifications and safety standards.

2. Material Selection

Choosing the right materials is essential to ensure durability and performance of the 3D printed components. Ceksan Sweepers works closely with material manufacturers to select high-quality, tough, and lightweight materials suitable for road cleaning truck operations. These materials exhibit excellent wear resistance, chemical stability, and are capable of withstanding harsh working conditions.

3. Printing and Testing

Once the design and material selection processes are complete, Ceksan Sweepers utilizes advanced 3D printers to manufacture the components. The printed parts are then rigorously tested in real-world scenarios to validate their performance, durability, and safety. This thorough testing ensures that only the highest quality parts are incorporated into their road cleaning trucks.

Conclusion

Ceksan Sweepers has embraced the benefits of 3D printing technology to elevate the performance and efficiency of their road cleaning trucks. Through customization, enhanced performance, rapid prototyping, cost savings, and careful implementation, they have established themselves as trailblazers in the industry.

By staying at the forefront of technological advancements, Ceksan Sweepers continues to deliver innovative, high-performance road cleaning trucks that meet the evolving needs of their customers. With 3D printing as a core element of their manufacturing process, they are driving progress and setting new standards in the road cleaning industry.

Experience the power of 3D printing with Ceksan Sweepers today and witness the remarkable difference it can make in road cleaning operations.