Label Machines for Clothing: Revolutionizing the Fashion Industry

In the fast-paced world of fashion, effective labeling is crucial for branding, compliance, and consumer information. A label machine for clothing serves as an invaluable tool for manufacturers and designers alike. This article delves deep into the importance of label machines, their functionalities, and how they can enhance your clothing business.

The Role of Labeling in the Fashion Industry

Labeling in the fashion industry goes beyond mere identification. Labels communicate essential information about a product, including:

- Brand Identity: Labels establish brand presence and create customer recognition.

- Care Instructions: Labels inform consumers about washing, drying, and ironing guidelines to maintain product longevity.

- Materials Used: They provide information about the fabric composition, which is vital for consumers with allergies or preferences.

- Size and Fit Details: Accurate sizing can significantly reduce return rates and enhance customer satisfaction.

- Compliance Messages: Labels fulfill legal requirements in many regions, ensuring that products comply with regulations.

What is a Label Machine for Clothing?

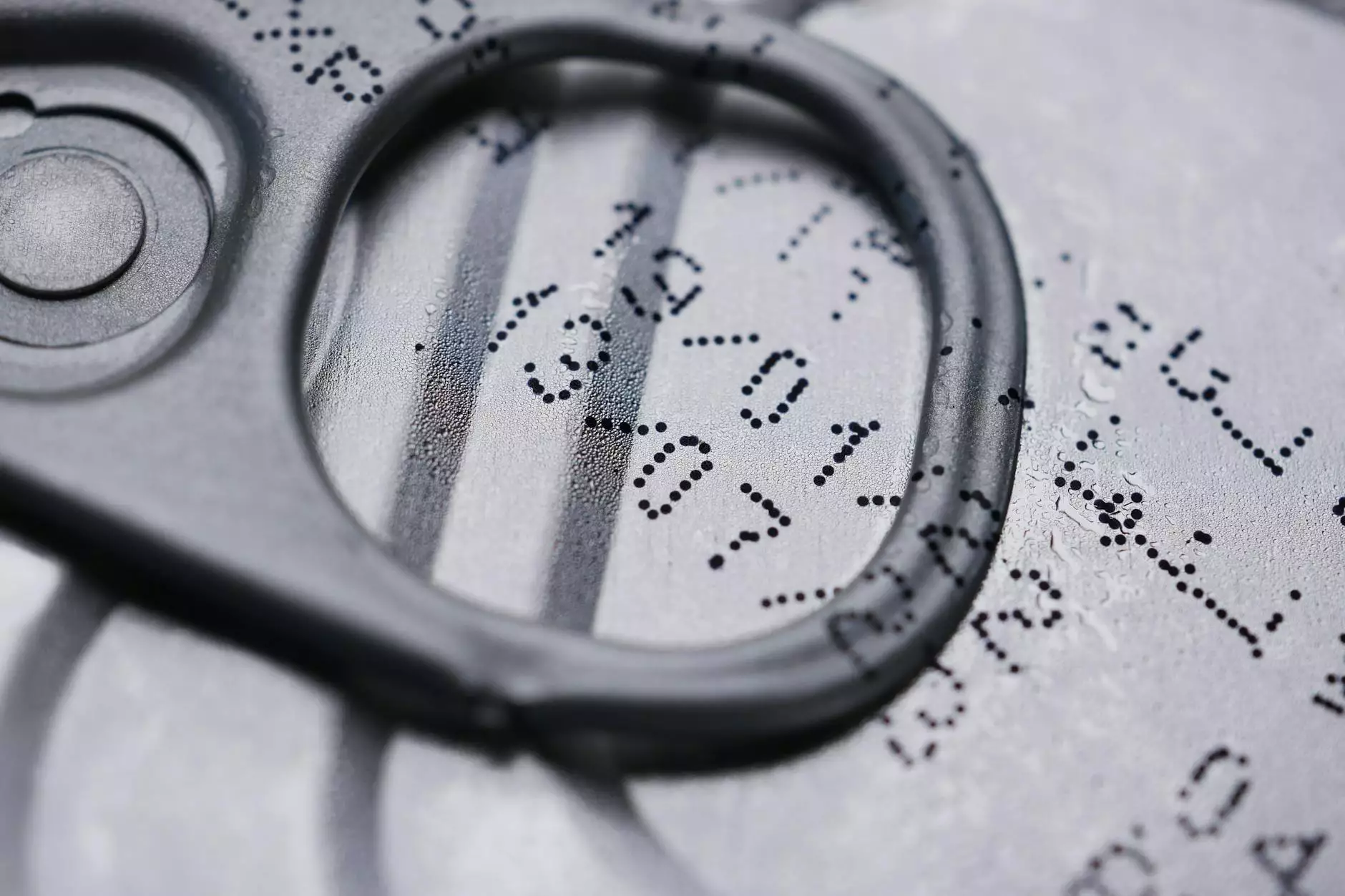

A label machine for clothing is a specialized device designed to print and apply labels to garments efficiently. These machines come in various forms, including thermal transfer printers, inkjet printers, and direct thermal printers. Each type has its unique advantages and is suited for different labeling needs based on factors such as speed, volume, and color.

Types of Label Machines

Understanding the different types of label machines can help businesses choose the right device for their needs:

- Thermal Transfer Printers: These machines use heat to transfer ink from ribbons onto label material. They produce high-quality, durable labels that resist fading and smudging.

- Direct Thermal Printers: These printers use heat-sensitive paper that darkens when exposed to heat. They are often less expensive and suitable for short-term labeling needs.

- Inkjet Printers: Ideal for businesses that require colorful, high-resolution labels. They use liquid ink to create vibrant designs but may not be as durable as thermal labels.

- Label Applicators: These machines automate the label application process, significantly speeding up production and ensuring consistent placement on garments.

Benefits of Using a Label Machine for Clothing

The implementation of a label machine for clothing can yield numerous benefits that enhance overall productivity and brand perception:

1. Efficiency and Speed

Label machines can dramatically increase production speed compared to manual labeling. Efficient labeling reduces labor costs and accelerates the time to market.

2. Consistency and Quality

Automated labeling ensures that every garment has a label that meets a uniform standard, which is vital for maintaining consistency in brand presentation. High-quality labels can also withstand washing and wearing, which is indispensable in the fashion industry.

3. Customization Capabilities

Many label machines offer customization options, allowing businesses to print unique designs, logos, and text that reflect their brand identity. Custom labels can help garments stand out in a competitive market.

4. Cost-Effectiveness

While the initial investment in label machinery may seem significant, the long-term savings achieved through increased efficiency, reduced errors, and lower labor costs can more than compensate. In addition, businesses can avoid outsourcing labeling, leading to further savings.

5. Improved Brand Awareness

Labels play a crucial role in brand recognition. A well-designed label can capture attention and communicate the essence of the brand. This can lead to improved brand loyalty and increased repeat purchases.

Choosing the Right Label Machine for Your Business

When selecting a label machine for clothing, several factors must be considered to ensure it meets the specific needs of your business:

1. Volume of Production

Assess the amount of labeling required. High-volume businesses may need more robust, faster machines, while smaller operations can opt for more economical models.

2. Label Material Compatibility

Different machines support various label materials, including fabric, paper, and synthetic substrates. Choose a machine that is compatible with your desired label material.

3. Print Resolution & Quality

If your clothing line requires high-resolution graphics and logos, then selecting a printer with superior print quality should be a priority.

4. Budget Considerations

Calculate the total costs, including initial purchase price, maintenance, and supplies. Invest in a machine that provides the best value for your budget.

5. User-Friendliness

A user-friendly interface simplifies operations and reduces training time for employees. Look for machines with intuitive controls and clear documentation.

Integrating Label Machines into Your Production Workflow

Integrating a label machine for clothing into your production process can be seamless if done strategically:

- Training Staff: Proper training will ensure that your team can operate the equipment efficiently. This includes understanding how to load labels, operate the software, and maintain the machine.

- Software Integration: Most modern label machines can integrate with existing design and production software. This streamlines the workflow and minimizes errors.

- Regular Maintenance: Establish a maintenance schedule to keep the machine in optimal working condition, avoiding unexpected downtime.

- Feedback Mechanism: Encourage staff to provide feedback on the labeling process to identify areas for improvement.

Future Trends in Labeling Technology

The labeling industry is constantly evolving, with innovations shaping its future. Here are some trends to watch out for:

1. Eco-Friendly Labels

As sustainability becomes increasingly important, businesses are looking for eco-friendly label materials and printing processes that minimize environmental impact.

2. Smart Labels

With advancements in technology, smart labels that utilize QR codes or NFC technology can enhance consumer engagement and provide additional product information.

3. Digital Labeling Solutions

Digital printing technologies are offering greater flexibility and customization options, allowing businesses to print small runs without significant cost implications.

Conclusion

In conclusion, adopting a label machine for clothing is not just a matter of convenience; it is a strategic decision that can impact branding, efficiency, and overall business success. By investing in the right labeling technology, clothing manufacturers can enhance their product offerings and increase customer satisfaction. As the industry evolves, staying ahead with the latest labeling innovations will be crucial for success.

For businesses looking to upgrade their labeling processes, DurafastLabel.com offers a range of high-quality label machines designed to meet the diverse needs of the clothing industry. Explore your options and take your fashion business to the next level with efficient, reliable labeling solutions.